Description

The making of gable bags: Lead Custom Boxes is here to make the most amazing gable bags for you. We make the gable bags with care and delicacy. Our team is here to astonish you with quality services.

Gable bags serve their purpose for storing lighter foods. For example, brownies, pastries, burgers, sandwiches, and many more are placeable. The making of gable bags is done with high time consideration and attention.

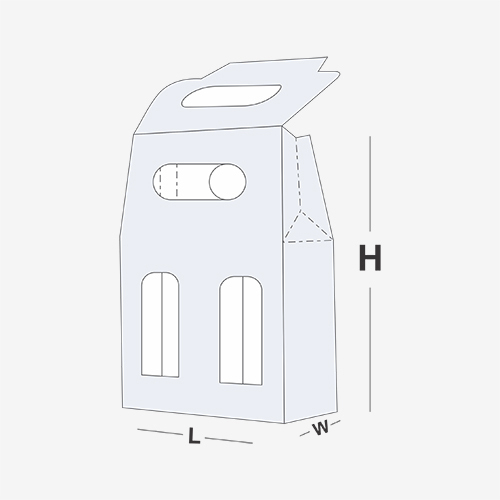

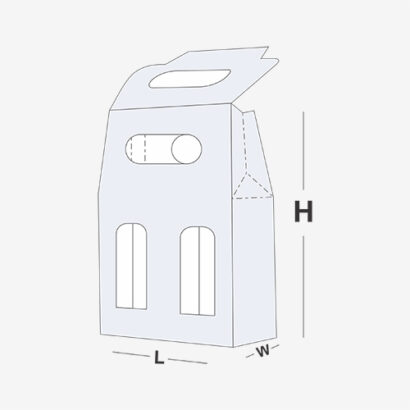

The bag contains 6 panels and 2 flaps. 2 side panels, 2 bottom closure panels, one rear panel, one front panel, and two top flaps are obtainable. The bottom closure panels are tucked within each other and the side panels are also tucked inside.

Also, the top flaps are joined with each other to make the top hanger of the gable bag. Moreover, we use Kraft paper and card-stock material. Both the materials vary in thickness whereas the ideal thickness is 10-12 pt.

we use Kraft paper because it is nature-friendly and resilient at the same time. Our purpose is to make the most incredible gable bags for our clients. Also, we use the hangers on the top to make them easier to carry.

Thus, customers can bring them anywhere conveniently. Designing them to increase your sales A gable bag not only helps in storing foods but also attract your customers. All the food brands focus on making their gable bags very interesting and animated.

Therefore, more customers are attracted to their packaging. An immense variety of options is available. Firstly two diverse coatings are obtainable.

The gloss coating increases the glamor and shines in your bags. Hence, you get bright and radiant gable bags. Otherwise, the matte coating provides dim and non-lustrous results.

The gable bags look very subtle and shady. Secondly, printing choices are also present. Printing increase the liveliness of your gable bags which is why customers show interest in them.

We make sure that we provide you with a vast variety so that you have a wide range of options to choose from. Digital printing presents basic results as drums and rollers are present. The rollers apply ink on the gable bags.

The technique is really good but a very common one. Otherwise, the offset printing has metal plates through which the ink is applied. it spread the ink beautifully and equally on all sides.

Also, it is best to use offset printing for printing a bundle of bags together as you can save money. Moreover, we also provide you with Add-ons. Spot UV is a trending Add-ons as it serves the purpose of matte and gloss both.

The inner corners of the bags are filled with light and shimmer whereas the rest of the box is dull. You can use this if you want to save some money. Furthermore, foil stamping of a variety of colors is possible.

Foiling makes the boxes a bit more creative and artistic. Creating a bond with our customers: Lead Custom Boxes is always here to listen to your suggestions and queries. We realize the need for communication and co-operation between clients and the company.

Therefore, we are available 24/7 to cater to all your needs. Our customer care staff is highly responsible and friendly. They will solve your problems in no time.

We offer free shipping to all our clients because we value your money. The delivery time is within 6-8 business days and your bags will be delivered in their real state. Order your gable bags now and avail of some amazing discounts.

These are for all our old and new patrons. Happy shopping! Have a nice day!

Reviews

There are no reviews yet.